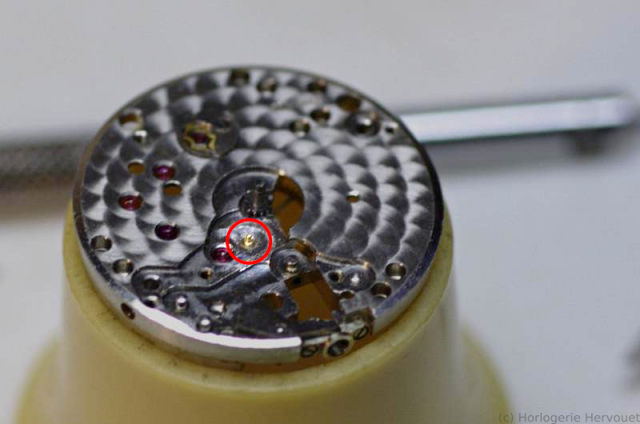

On this gold Longines, a strange problem occurred: the pivot of the minute wheel just … broke. Here is it pictured, after is was replaced and set in the main plate :

The 8mm Lorch lathe was quite useful: it has a range of pivot drills, allowing to quickly turn small diameters. 0.52mm (baseplate) and 0.35mm (minute wheel) were needed.

It was then finished by hand using a pivot file and a burnisher to the exact diameter and length. Lastly, it was precisely set in the baseplate so that the minute wheel do not touch it (but also do not touch the hour wheel): the tolerance is not bigger than 0.01mm. One would have thought the worst was over, but the hairspring needed some work too. A previous “watchmaker” trying to repair this watch damaged it with ham-fisted hands.

It was bent: not flat anymore, it touched the arms of the balance wheel. Also, the terminal curve was completely off, obviously. With a light touch and #5 Dumont tweezer, all is good again and from there, it is business as usual.

But the folks at the Longines plant made a last nasty surprise: the cap jewels for the Incabloc shockproof system are white. Easy to lose!

It feels nice to see this one ticking, and even nicer to see it leave the workshop… reminds me too vividly of a tricky repair.